blob-article

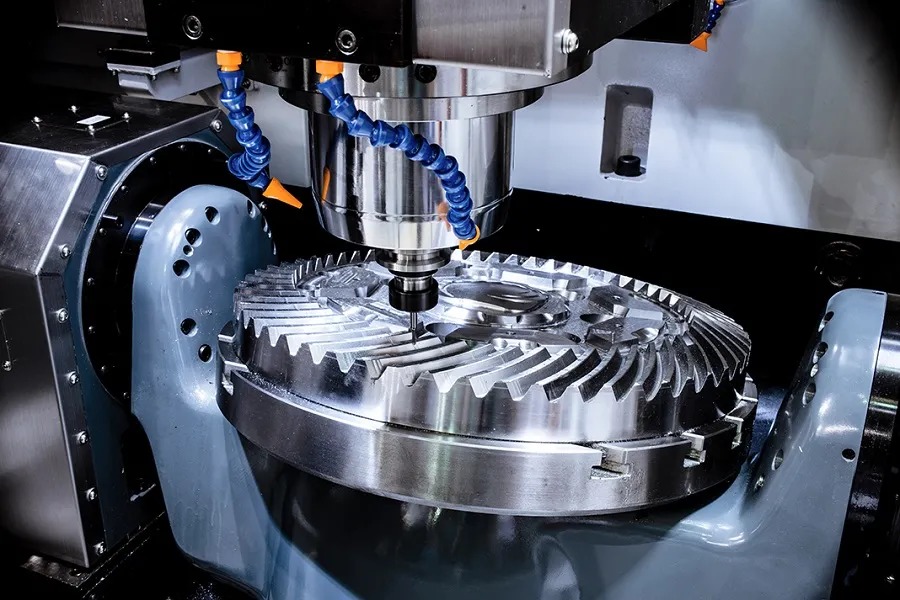

Selecting a right machine for your Tool Room and Production purposes is sometimes a complex task, but actually its very simple. Let us explain how to do this for various machines.

The primary objective is to match the job machining data with machine specifications. Following table shows a ready reference for various types of machines that will help to decide the size of machine.

How to Select Metal Cutting machines?

|

Sr |

Machine Category |

Job parameters |

Machine Specifications |

|

1. |

Turning such as lathe Turning Centres & Lathe |

1.Job Dia, 2.Job length, 3.Material of Job, |

1.Job material :Center Height,

|

|

2. |

Vertical Milling conventional or CNC or VMC, s |

1.Job size (L x W x H) 2.Job Weight 3.Job Material 4.Amont of stock to be removed 5.type of operation; Rough, semi-finishing or Finish Machining precision Tool room or production machining |

1.Table travel 2.Table Load 3.Motor Power 4.Speed Range Relates to machine frame and optional accessories like linear scales. 5.Tool Changer configuration, Tool Change time, Rapid Speed of Axis |

|

3. |

Horizontal Milling, Horizontal Boring. Horizontal Machining Centre |

Similar to above |

Similar to above but HMCs and Horizontal machines are suit for gear Boxes, large size Mold bases, four side machining |

|

4. |

Surface Grinding Machines |

Job Material, grinding length, Grinding depth, Finish |

Table Load, Table Travel Hydraulics, Working Table Speed, Wheel Size

|

|

5. |

EDM Spark Erosion machines |

1. Job Size Job Material, 2.Electrode Material, Depth of cut |

1.Table Travel, Max. Workpiece weight, 2.Tank Capacity, Max. Working Current |