Hot Chamber Die Casting

Machines

Industrial Solutions

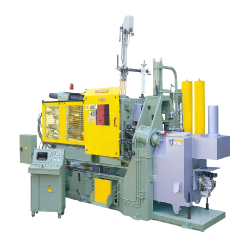

PRODUCER Zinc Die Casting (30 - 130) Ton

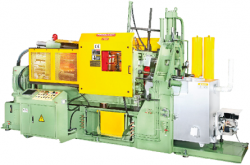

PRODUCER Zinc Die Casting (160 - 500) Ton

What are Hot Chamber Die Casting Machines?

Hot chamber die casting is a high-speed and efficient die casting process for metals, in which molten metal is pushed into molds through a gooseneck system permanently submerged in molten metal. The process is well adapted to low melting point metals such as zinc, magnesium, and lead alloys.

At ATPL, we are experts in high-performance Hot Chamber Die Casting Machines such as our PRODUCER Zinc Die Casting series for precise production of quality parts.

Key Advantages of Our Hot Chamber Die Casting Machines

Lower Production Cycles - Suitable for high volumes of production

Energy Conservation - Less power requirement in comparison with cold chamber

High Metal Quality - Eliminates impurities in final product

Longer Machine Life - Heavy build can stand constant use

Operation is simpler - Simpler controls and maintenance

Why Would One Use a Hot Chamber Compared to a Cold Chamber?

Hot chamber machines are better with:

-

Faster cycle times because metal is always molten and available

-

Ideal for zinc alloys and other low-melting-point metals

-

Reasonably priced for big production runs

-

Simpler maintenance with less moving parts

Common Applications

-

Our hot chamber die casting equipment is applied on:

-

Automotive parts (gears, brackets, housings)

-

Electrical and connector parts

-

Consumer product parts

-

Plumbing parts

-

Precision industrial parts

FAQs For Hot Chamber Die Casting

1. What metals are cast using hot chamber die casting?

Mainly zinc, magnesium, lead and other alloys with a melting point under 600°F. Aluminum would most likely need cold chamber machines.

2. How is a hot chamber different from cold chamber casting?

Hot chamber has molten metal reserved within the machine, whereas cold chamber has separate melting and manual metal transfer for each shot.

3. What is the volume of production apt for hot chamber machines?

They are best suited for medium to high volume production between thousand to million parts.

4. Who utilizes hot chamber die casting?

Automotive, electronics, consumer products, and industrial manufacturing are large users.

5. How accurate are hot chamber castings?

They create very precise parts with great surface finish and close tolerances.

6. What type of maintenance are these machines?

Regular lubrication, seal and component check, and clean up between runs.

7. Do hot chamber machines have the ability to create detailed part designs?

Yes, they are very good at creating complex thin-walled parts with excellent detail.

8. How long does tooling last?

Well-maintained dies will make hundreds of thousands to millions of parts.

9. What safety features are incorporated?

Our machinery includes thermal controls, safety interlocks, and emergency stop mechanisms.

10. Why use ATPL for hot chamber die casting?

We provide dependable PRODUCER series machines with seasoned support for trouble-free operation and optimal uptime.

Why Work with ATPL?

PRODUCER Series Reliability - Established performance in tough applications

Application Expertise - Help in choosing the right solution for your need

Total Support - Installation to maintenance

Quality Assurance - Accuracy and long-lasting machines

Whether you are expanding production capability or putting in new machinery, our hot chamber die casting solutions offer the performance and dependability that your shop demands.