Cnc Metal Cutting

Machines

Industrial Solutions

Quick Jet 5 Axis Machining Center

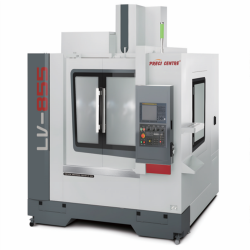

PRECI CENTRE Machining Center (LV Series)

LEADWELL Machining Center (VE Series)

Leadwell CNC Machining Centers (NV Series)

Quick jet Double Column

CNC Metal Cutting Machines: Precision, Power, and Performance

In India, ATPL Online is the go-to for advanced solutions in CNC metal cutting, offering machines from leading manufacturers in China. Our powerful Quickjet and Preci Centre machining centers as well as Leadwell branded ones are the most accurate, quickest, and most durable in the market. We manufacture parts used in the automotive, aerospace, toolroom, and metal fabrication industries.

Why select ATPL Online for CNC Metal Cutting Machines?

Contrary to popular practices, we directly source equipment from ISO-certified manufacturers based in China, removing the middlemen monopoly and selling CNC machines for cheaper in India.

We offer Custom Solutions as well, allowing the user to change automation settings, spindle speed, and axis configuration according to their production requirements.

With our advanced manufacturing capabilities, we provide quality assurance for the machines fulfilling CE and RoHS requirements along with international safety standards.

Last but not least, we ensure our clients receive complete ATPL Online support including technical assistance, backup parts, and guidance with installation.

We offer expedient Leadwell and Quickjets as well as other bone machinery alongside our line of CNC machining centers.

1. CNC Machining Centers - Leadwell

Key Features

Turn-key sophistication: Up to 15,000 and higher rpm spindles, rigid cast iron structures, electric drive motors coupled to linear guideways.

Automatic tool changers with preset 24 plus tools and dialogue controls that respond to programming for more intricate processes.

For fabrication of automotive components, aerospace engineering dies, and metals with complex geometries.

Why use Leadwell?

Needle-sharp precision with micron-level accuracy compliments high volume, high demand use. Coupled with low operating costs and minimal downtime, makes them the industry ideal.

2. CNC Machining Centers - Quickjet

Key Features

Increased Toughness: . Stops work at 15 and restarts at 30hp for demanding stainless steel and titanium alloys.

Large Work Envelope: Up to 2000x1200x800mm for large size workpieces.

Coolant Systems: Tool life is prolonged, and heat is dissipated using high-pressure coolant systems.

Why Quickjet?

Designed for shipbuilding, construction, energy, and other sectors that require heavy-duty fabrication.

3. Preci Centre Machining Centers

Key Features:

4th/5th Axis Integration: Complex contouring and machining at various angles.

Thermal Stability: Accuracy-maintaining compensation systems for lengthy operations.

Uses: Manufacturing of medical devices, precision molds, and gears.

Why Preci Centre?

Ideal for high-difficult tolerance markets demanding complex, multi-surface machining.

Industries We Serve

Automotive: Prototyping and engine blocks, as well as transmission parts.

Aerospace: Components of structural and turbine blades.

Tool & Die: Stamping die and injection molds.

General Engineering: Hydraulic components and precision shafts.

FAQs

Q1: What is the price range of Leadwell CNC machines in India?

Prices start with 3-axis models priced at ?25 lakhs and 5-axis models reaching up to ?1.2 crore.

Q2: Can thick steel plates be cut by Quickjet machines?

Of course! Steel plates up to 100mm thickness are easily managed by Quickjet’s high-torque spindles and rigid framed machines.

Q3: CAD/CAM integration Preci Centre machines do support?

Of course. They are integrated with Mastercam, SolidWorks, and Siemens NX.

Q4: Is these machines specifications suitable for Indian power requirements?

All machines are set to 415V/50Hz.

Boost Your Production with ATPL Online!

We supply CNC metal cutting machines, including the high-speed Leadwell VMCs, heavy-duty Quickjet gantries, and the Preci Centre HMCs, with unparalleled efficiency. Request a quote today!