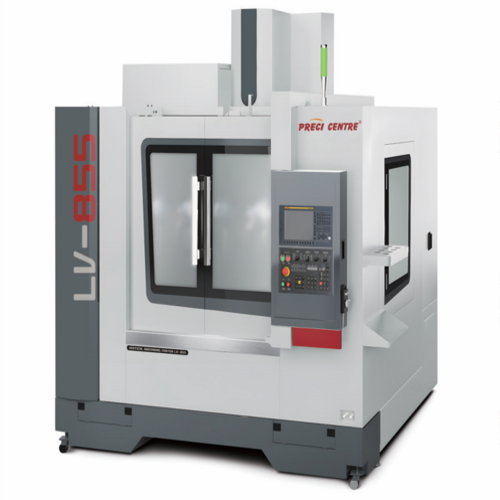

| Model No. | LV-855 | LV-1160 | LV-1265 | V-1380 | LV-1580 |

| Travel (X / Y / Z) mm | 850/550/550 | 1100/600/600 | 1200/650/600 | 1300/800/750 | 1500/800/750 |

| Table Size mm | 1000×550 | 1200×600 | 1200×600 | 1500×700 | 1200×600 |

| Spindle Speed rpm | Standard 8000 and Optional 10000 / 12000 / 25000 |

| Mass of Machine Kg | 6000 | 7800 | 8500 | 11000 | 12000 |

The LV series can be offered with different types of CNC controllers like Mitsubishi, Fanuc or Siemens. It has directly coupled motors with absolute encoders matched with class C3 ball screws. Good assembling techniques and in process quality control makes the LV series deliver high accuracy and high precision performance in die and mold making or any other general-purpose machining application. It can be equipped with several performance options like the 4th axis rotary table, auto tool length measurement and workpiece measurement options making it fit for any type of CNC machining application.

- Brief Product Specification: