Milling Lathe Grinder Drills

Machines

Industrial Solutions

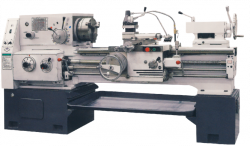

Hi- Cut Precision Lathe Machines

Precicut M1TR Milling Machine

SURFACE GRINDER

RADIAL DRILLING MACHINE

Power Hacksaw

BENCH DRILLING MACHINE

PILLAR DRILLING MACHINE

PEDESTRAL GRINDER

Precision Machines for All Purposes

We at ATPL offer complete machining services for workshops, factories, and manufacturing plants across India. Our line of industry-standard machines offers the ideal blend of precision, reliability, and performance to meet every metalworking need.

Our Line of Precision Machines

We handle four significant types of workshop machinery:

1. Lathe Machines

Workhorse of any machine shop, our lathes convert raw material to accurate parts through turning, facing, and threading operations. Suitable for the production of parts of high precision cylindrical in nature.

2. Milling Machines

Multi-purpose workhorses for metal cutting by rotary cutting tools. Most suitable for fine machining operations such as slot cutting, drilling, and contouring on different materials.

3. Drilling Machines

From radial drills for heavy-duty applications to bench-top systems, our machines create precise, consistent holes in metal components of any size.

4. Grinding Machines

Our grinders remove material with abrasive wheels to create perfectly flat surfaces for mirror finishes and extremely accurate measurements.

Why These Machines Matter in Modern Workshops

Current production needs require equipment that delivers:

-

Consistent precision across production runs

-

Durability to last under repetitive industrial use

-

Versatility to handle a range of materials and applications

-

Operator-friendly design that improves productivity

-

Consistent performance that reduces downtime

Our machines tackle these challenges head-on, enabling any-sized shop to produce quality results effectively.

Applications Within Industries

These basic machines are used in various industries:

-

Automotive - Engine components, transmission components

-

Aerospace - Precise aircraft components

-

Tool & Die - Mold making, cutting tools

-

General Engineering - Machinery components, fittings

-

Fabrication - Structural components, frames

-

Maintenance - Repair and rebuild of equipment

Machine Tools FAQs

1. What is the general contrast between milling machines and lathes?

Ans. Lathes turn workpieces against fixed tools, whereas milling machines feed rotating cutting tools across fixed workpieces - two inverse methods of metal shaping.

2. How do I decide between various kinds of lathes?

Ans. Think about your average workpiece size, level of precision needed, and quantity of production. Our specialists will direct you to the correct traditional or CNC model.

3. What are some things milling machines are better at doing than other machines?

Ans. Milling is good at producing intricate shapes, slots, and contours that cannot or are hard to be accomplished with other machines.

4. Why do I need a separate drilling machine when my milling machine can drill?

Ans. Single-function drills provide quicker setup for rigid drilling operations and sometimes added stiffness for hard materials.

5. Under what circumstances would grinding be necessary after milling or turning?

Ans. Grinding achieves smoother surfaces and closer tolerances when standard machining is not precise enough.

6. How critical is rigidity in a machine to quality output?

Ans. Very critical. Rigid construction prevents vibration, creating smoother finishes and extended tool life.

7. Are the machines safe for a novice operator?

Ans. Yes, provided proper training is given. We suggest practicing with simpler manual versions first before proceeding to more sophisticated CNC equipment.

8. What type of maintenance do these machines need?

Ans. Regular maintenance, lubrication, and checking of major parts will keep your machines running for decades.

9. How do I decide how large the machine should be for my workshop?

Ans. Keep in mind your largest average workpiece, floor space, and power supply. Our staff can call on you to consult.

10. What are the safety features I should look for?

Ans. Key features are emergency stopping, adequate guarding, overload protection, and firm foundations.

11. How long will they last?

Ans. With good maintenance, our machines provide decades of trouble-free use in factory situations.

12. Can one machine be used to perform more than one operation?

Ans. There are a few combination machines, but specialized units are best at what they are designed to do.

13. What is the benefit of geared head machines?

Ans. Geared transmissions deliver more torque on deeper cuts and yet allow precision and control.

14. How do I decide between manual and CNC machines?

Ans. Manual is best for small lot sizes and less complex jobs, while CNC is best for complex, repeat production work.

15. What types of materials can these machines handle?

Ans. All general metals like steel, aluminum, brass, and alloys, as well as some plastics and composites.

16. How important is post-sales support?

Ans. Critical. Correct installation, training, and ongoing support ensure you get maximum value out of your investment.

17. What are the power needs of these machines?

Ans. Variable by size and application. We have models to fit everything from small shops to heavy industry.

18. Can we retrofit or upgrade existing machines?

Ans. Yes, many manual machines are suitable for retrofit with digital readouts or even complete CNC conversion in other situations.

19. How do I have consistent results run after run?

Ans. Quality equipment and rigid construction, along with proper operating habits and training, and maintenance practices.

20. Why do business with ATPL for machine tools?

Ans. We pair quality gear with expert counsel and substantial support to ensure your shop prospers.

The ATPL Machines Advantage

As our business partner, you'll enjoy:

-

Machines industry-standard that professionals trust

-

Expert counsel to help you choose the optimal set of equipment

-

Full support for the life of your gear

-

Competition-cutting prices without sacrificing quality

-

Flexible terms to fit your very specific needs

New equipment or new machines to take the place of old ones, our equipment provides the performance and reliability your business needs to succeed.