blob-article

How To Select An Injection Moulding Machine

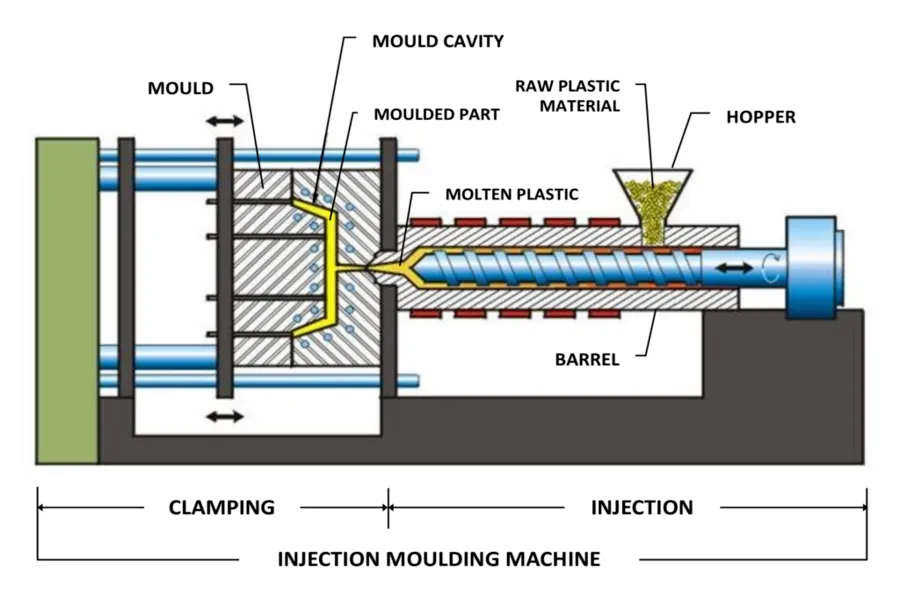

In order to make easy decisions about the mother machines in your injection molding shop, I would like to present here some basic and easy to understand key points that one needs to consider before buying an injection moulding machine

1. Shot Weight/ Theoretical Volume –

This is listed in the product catalogue and should be mapped with the proposed shot weight which is the sum of total product weight (all cavities) along with the runner and the gating system. The catalog shot weight must be 30-40% more than tbe proposed shot weight. The theoretical volume can be converted in to weight for different plastic materials using their specific gravity.

2. Platen Size/ Distance Between Two Tie Bars-

This is also listed in the machine catalogue and should be co-related with the size of the mould worked out based on the number of cavities that are to be moulded.

3. Type Of Material-

The type of material to be moulded decides the injection screw and the material of the injection screw. For example bimetallic screws are used when molding Glass filled Nylon.

The dia of the screw and the corresponding injection pressure are co-related with the material, form factor and the wall thickness of the component to be molded

Based on the above three factors one can fix the tonnage and the size of the injection unit.

Some other factors that matter while deciding an injection moulding machine are:

• Energy consumption

• Possible cycle time

• Automation

Through these considerations one can decide the machine should be with servo motor with pump or fixed pump or part extraction robot and the auto feed system for raw material.

Keeping all these in perspective can help one to estimate the machine size and configure the type and requirement of injection moulding machine.