blob-article

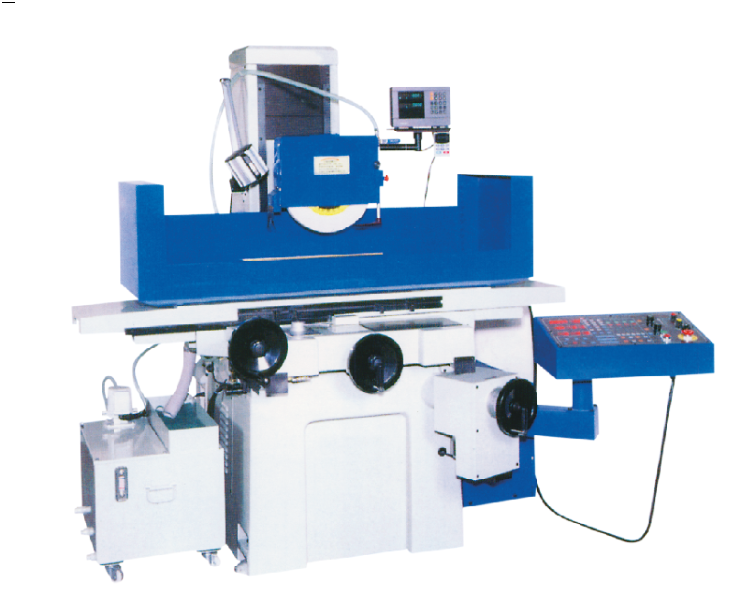

Surface grinding machine is one of the Essential Equipment found in Various sectors. These are utilized to smoothen the surfaces of metals in a finishing process with minimum error and great accuracy. Because these machines have flatness and smooth surface finishes, they hold immense importance in manufacturing, automotive, aerospace, and tool-making industries. Improvements in technology make sure that modern world surface grinders give higher precision, quicker production time, and finer surface finishes.

A Surface Grinding Machine: What Is It?

An industrial tool used to give flat surfaces a superior finish is a surface grinding machine. It accomplishes this by cutting material away from the workpiece using a revolving grinding wheel. In common setups the workpiece is held in place with a magnetic chuck or vice, and the wheel rolls over it, polishing its surface. Surface grinders are used widely within manufacturing, metalworking, the automotive sector, and aerospace to accurately polish surfaces.

1. Precision and Accuracy in Surface Finishing

Surface grinders are capable of producing a smooth and flat surface with Precise Limits. This makes them essential for industries where accuracy is key. For example, when working with components like gears, bearings, or hydraulic valves, even the smallest deviation in surface finish can lead to inefficiency or product failure.A surface grinder ensures that the workpiece is within the required dimensions and has the quality surface.

Such precision provided by a Precision Grinding Machine helps improve the quality of the product altogether so that it fits into its functional application without defects such as poor surface finishing or misalignment.

2. Improved Surface Quality

The machinery usually involves a surface grinding machine to deliver highly smooth finishes of workpieces. They remove rough spots, burrs, or imperfections that might exist along the material's surface. Such a result is aesthetically pleasing and might be crucial in cases such as the automotive or consumer electronics industries where the final product appearance is critical.

A smooth finish on the surface helps reduce friction, which in turn can prove critical in wearing parts such as gears, bearings, and some parts of machinery. Reduced friction ensures better performance and longer lives for these parts, thus saving much maintenance and replacements over time.

3. Versatility in Application

A surface grinder can be applied to grind lots of materials ranging from metals to plastics and ceramics. It can thus be used from steel and aluminum to even softer materials, such as brass or copper. This versatility places it as a very important tool among manufacturers who engage in the fabrication of a range of materials.

Precision Grinding Machine can be altered to grind different shapes of surfaces, such as flat surfaces, stepped surfaces, and complex contours. Its ability to work on different shapes and materials make it one of the favorable tools in manufacturing industries.

4. Increased Productivity and Efficiency

In an industry, the output and efficiency can be boosted dramatically by using a Precision Grinding Machine. Surface grinders work with great precision and speed, enabling many manufacturers to process huge batches of workpieces at high speed and still maintain quality.

In contrast to the other more traditional ways of grinding manually that are time-consuming and inconsistent, surface grinders offer machinery-based automated solutions with faster turnaround rates. This indicates that production lines can be operated at their maximum capacities, while workers attend to other important jobs, therefore, making surface grinders a perfect investment for businesses in need of high volumes without losing on quality.

5. Cost-Effectiveness

The Extended Period cost savings make the initial investment in a surface grinding machine a Valuable Asset for many industries. In addition to the increased efficiency, the reduced material waste and lower maintenance costs of surface grinders save a business a significant amount of money over time.

For instance, achieving the desired surface finish on the first attempt can save manufacturers from rework or scrapping of parts. The precision provided by surface grinders also minimizes the possibility of errors in assembly, which can be costly to repair or replace.

More importantly, because of the minimal friction and wear associated with the Precision Grinding Machine, components obtained from such machines have relatively longer lifetimes and thus get replaced and repaired less often.

6. Minimal Material Waste

The main goal in manufacturing is to eliminate waste for environmental and financial purposes. Surface grinding machine are quite efficient in the removal of material from workpieces without wasting much material. Since the grinding wheel removes a precise amount of material from the surface, there is little scrap of leftover material, which makes surface grinding a more economical and environmentally friendly option compared to other methods.

This precision also saves the overall cost of raw materials since fewer parts have to be discarded because of imperfections.. By reducing material waste, surface grinding machines contribute to more sustainable manufacturing practices.

7. Improved Flatness and Parallelism

One of the principal benefits of grinding on a surface grinder is obtaining excellent flatness and parallelism. In industries such as aerospace and automotive, components must often be perfectly flat and parallel so that they may function properly.

Since a surface grinder may easily achieve a higher value for flatness, it is of immense value for industries requiring high tolerance levels. It guarantees that the parts will fit together as designed and that there will be no anomalies, and this is the only way to ensure the integrity and operation of the system.

8. Easy to Operate

Modern surface grinding machine are designed to be friendly and easy to use, due to advanced controls and automated systems that have proved more effortless than in the past. Most of the equipment does provide natural interfaces that let the operator change various parameters like grinding speed, feed rate, or cutting depth. This limits the learning curve for operators who are new while experienced machinists find it easy to fine-tune their operations for better results.

Besides, some surface grinders are even equipped with CNC systems that make the grinding processes fully automated. With CNC surface grinders, the operator can input precise specifications and the machine will automatically perform the grinding operation with minimal supervision.

9. Ability to Handle Complex Tasks

Though surface grinding machines are most commonly used for surfaces that are flat, they can be used for much more. Depending on the attachments and fixtures, surface grinders can be used for grinding non-flat surfaces, such as slots, grooves, or stepped parts. Therefore, this makes surface grinders very flexible, with many applications and industries possible.

Moreover, surface grinders can be used to perform other operations like cylindrical grinding, giving manufacturers even more functionality.

10. Enhanced Safety

Surface grinding machines are safer to Function over Manual Grinding.Modern surface grinders are fitted with Safety Mechanisms, including safety guards, emergency stops, and automatic shut off, which also protect the users from accidents. With proper education and adherence to safety protocols by the workers, the worker can safely handle the surface grinding machine and mitigate the Injury Threat accordingly.

Conclusion

The surface grinder provides numerous advantages to industries needing high clarity in production, effective production, and uniform surface finish. It will play a fundamental role in assuring quality and efficiency while making it cost-effective for any operation in the automobile, aerospace, or metal industries. Surface Performance Enhancement, saving material, and increased productivity will be the few contributions of the machine in the accomplishment of modern manufacturing operations. Investing in a surface grinder not only improves the precision and performance of your products but also helps drive Sustained Savings and operational efficiency.