blob-article

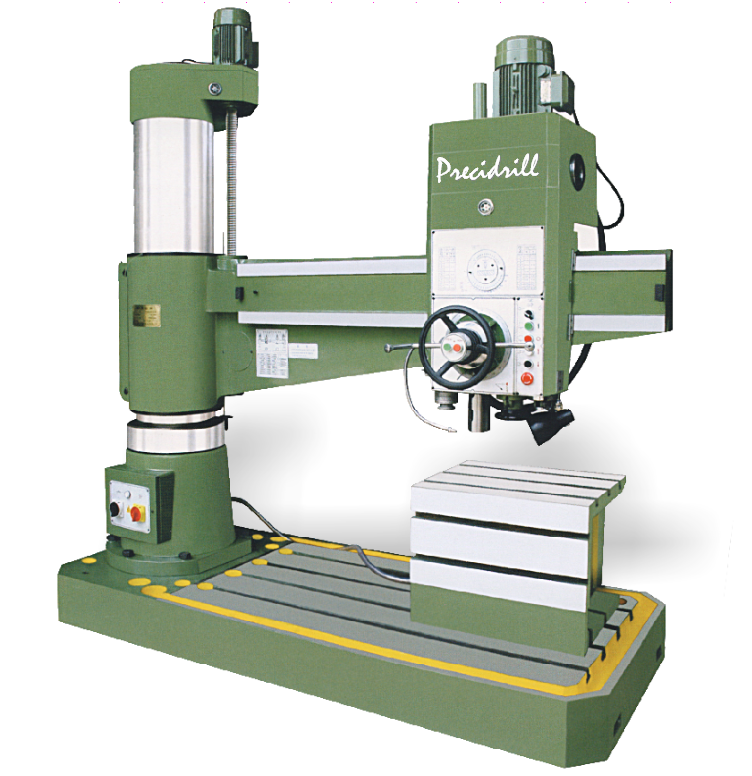

A radial drilling machine is among the most adaptable and strong machines applied in the drilling of holes into different materials like aluminum, carbon steel, alloy steel, and cast iron. It is very important to numerous industries such as construction, manufacturing, and metalworking, offering precision and efficiency in handling large workpieces. Flexibility in its operation allows users to drill holes of various sizes with ease. It can drill up to 75mm. The radial drill is an invaluable resource in all workshops and factories all over the world.

Other drilling machines are quite distinct as this radial arm can turn 360 degrees. Its design separates it from other machines and allows for the handling of heavy and long workpieces. It is ideal for any industrial application, small or big, regardless of whether components are extremely delicate or heavy-duty. Precision, durability, and consistent performance ensure intricate components or heavy-duty projects to be completed as intended.

What are the Components of a Radial Drilling Machine?

The industrial drilling solution consists of several key components:

1. Drill Bit and Chuck

The cutting tool which penetrates into the material is called the drill bit and on the other hand, there is a chuck holding the drill bit inviolable. A chuck can give a more accurate alignment that facilitates smooth drilling of the workpiece. This component is crucial for achieving clean and accurate holes.

2. Spindle

A rotating shaft, a spindle is mounted on radial antifriction bearings and is driven by a motor. The rotation is transmitted to the drill bit through the spindle. Therefore, with the spindle mounted on radial antifriction bearings, it smoothes the operation of drilling even when drilling goes on for hours.

3. Radial Arm

Industrial applications of steel have alloy steel as a combination of steel with other elements in order to improve the properties. The radial drill is designed to be sturdy enough for application on the toughness of alloy steel.

4. Base

The base of the machine is made of hardened cast iron to provide stability and absorb vibrations during operation. This ensures the machine remains steady, which is critical for precision drilling.

5. Rack and Pinion System

The rack and pinion system allows the drill head to move smoothly along the radial arm. This mechanism ensures accurate positioning of the drill bit over the workpiece.

6. Drill Head

The drill head contains the spindle, chuck, and motor. It can be moved in any direction, which simplifies the task of drilling at multiple locations with minimal repositioning of the workpiece. These components work in tandem to make the industrial drilling solution a very reliable and efficient tool for various drilling applications.

How to Maintain a Radial Drilling Machine?

Proper maintenance is called-for to ensure the longevity and optimal performance of an industrial drilling solution. Regular upkeep not only enhances efficiency but also reduces the risk of accidents. Here are some maintenance tips:

1. Daily Cleaning

Clean the machine following every operation so that it is free from dust and debris as well as shavings of metal. The workbench and surrounding area should be clear of clutter.

2. Lubrication

Regular lubrication of the moving parts like spindle, radial arm, and rack and pinion system keeps the running smooth without causing friction and rust. Use manufacturer-recommended oils to lubricate parts.

3. Inspect Drill Bits and Cutters

Check the drill bits and cutters for signs of wear or damage. Replace them if necessary to maintain drilling precision.

4. Check the Electrical System

The electrical wires, connections, and switches should be inspected for their good condition. Maintain the electrical box clean and ventilated.

5. Cooling System Maintenance

Clean the oil filter and cooling system regularly to prevent overheating and ensure efficient operation.

6. Stability Checks

Ensure the base and workbench are stable to avoid vibrations during operation. A stable setup improves accuracy and safety. It maintains the performance as well as prolongs the lifetime of your versatile drilling machine by observing these maintenance practices.

Radial Drill Machine drills through Aluminum, Carbon Steel, Alloy Steel, and Cast Iron. The primary benefit of a radial drilling machine is that it can drill into any material. It is widely used in the various industries, which require accurate drilling. Let's see further into its capacity:

1. Aluminum

Aluminum is a soft, lightweight metal used in the aerospace, automotive, and construction industries. The bit drills nice and clean holes in aluminum without distorting it.

2. Carbon Steel

Carbon steel is very strong and durable. This material can be drilled with the radial drilling machine efficiently and can be used for heavy-duty applications like manufacturing and construction.

3. Alloy Steel

Alloy steel is a combination of steel with other elements to enhance its properties. It is used in plenty of industrial applications. The radial drill is strong enough to withstand the toughness of alloy steel.

4. Cast Iron

Cast iron is brittle, and handling during drilling requires extreme care. With an adjustable radial arm and stable base, the radial drill is quite ideal for casting holes in cast iron without causing cracks or damage. This adaptive nature of the radial drilling machine makes it both versatile and essentially irreplaceable at workshops and factories.

Conclusion

A radial drilling machine is one of the versatile and reliable drills used in the manufacturing industry when accuracy in drilling is required. From aluminum to cast iron, the machine can take on anything. This makes the ownership of the machine necessary for every manufacturer. All the parts that make up the machine-the radial arm, the spindle, and the chuck-work harmoniously to make sure accuracy and efficiency are achieved with every operation.

The right maintenance will see to it that the machine is in good condition. Cleaning, lubrication, and inspection of the parts will improve its performance as well as serve for much longer periods. Its difference to industries from construction down to metalworking is it could be a big difference because of its capability to drill through heavy and large workpieces.

Whether it is a small workshop or large manufacturing units, an investment in a radial drilling machine can help significantly in achieving increased productivity with quality results. Its blend of precision and ruggedness is simply a wonderful requirement for contemporary applications.